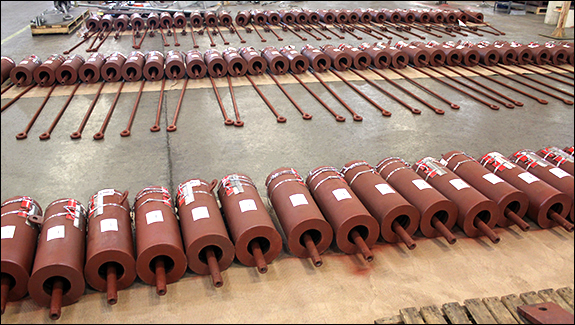

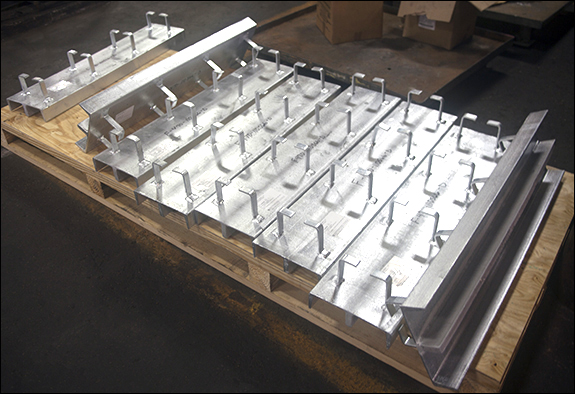

These screen guides were custom fabricated for a cooling tower at a chemical plant in Texas. These anchor bars are used to secure the screen guides to the concrete. These screen guides are 10″ in width and are 42″ in length. All components were completely fabricated from A36 carbon steel with a galvanized finish. Standard quality control inspections were performed before shipment.

Many plants, such as power, petroleum refineries, metal processing, and other industrial facilities are designed to use open recirculating systems utilizing cooling towers for heat transfer from condensers and other heat exchangers through a process called “latent heat of vaporization.”

Within these cooling towers, screen guides are used in a gravity-flow distribution system where supply water flows or cascades down over successive offset levels of horizontal screens or splash bars into a basin. These guides provide a means by which screens or splash bars are supported from a concrete structure. The screens are intended to lower the temperature of water by causing the water to spread over large areas to promote maximum exposure to airflow as it cascades from the top of the tower into the lower basin. One side of the guide provides a “slot” by which screens or other types of “surfaces” can be installed. The other side of the guides are fitted with bent “strip anchor bars” similar to those used for embed plates. As a manufacturer of embed plates, we also supply these for mining facilities, semiconductor plants, wastewater treatment plants, or any construction site where there is steel attached to a concrete panel or slab.

Within these cooling towers, screen guides are used in a gravity-flow distribution system where supply water flows or cascades down over successive offset levels of horizontal screens or splash bars into a basin. These guides provide a means by which screens or splash bars are supported from a concrete structure. The screens are intended to lower the temperature of water by causing the water to spread over large areas to promote maximum exposure to airflow as it cascades from the top of the tower into the lower basin. One side of the guide provides a “slot” by which screens or other types of “surfaces” can be installed. The other side of the guides are fitted with bent “strip anchor bars” similar to those used for embed plates. As a manufacturer of embed plates, we also supply these for mining facilities, semiconductor plants, wastewater treatment plants, or any construction site where there is steel attached to a concrete panel or slab.

PT&P REF. ORIGINAL POST 04102017

Read More